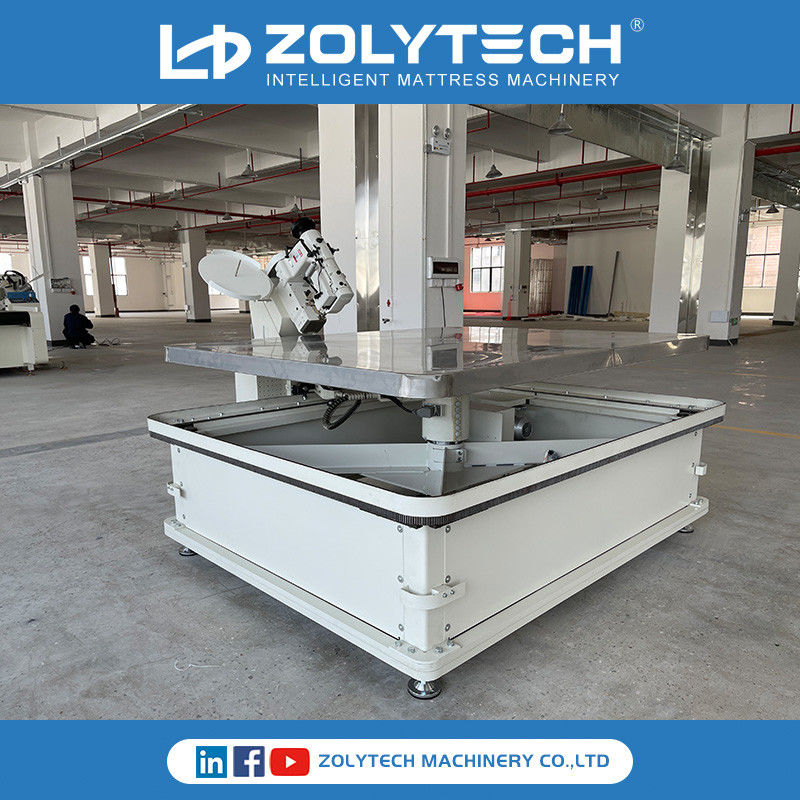

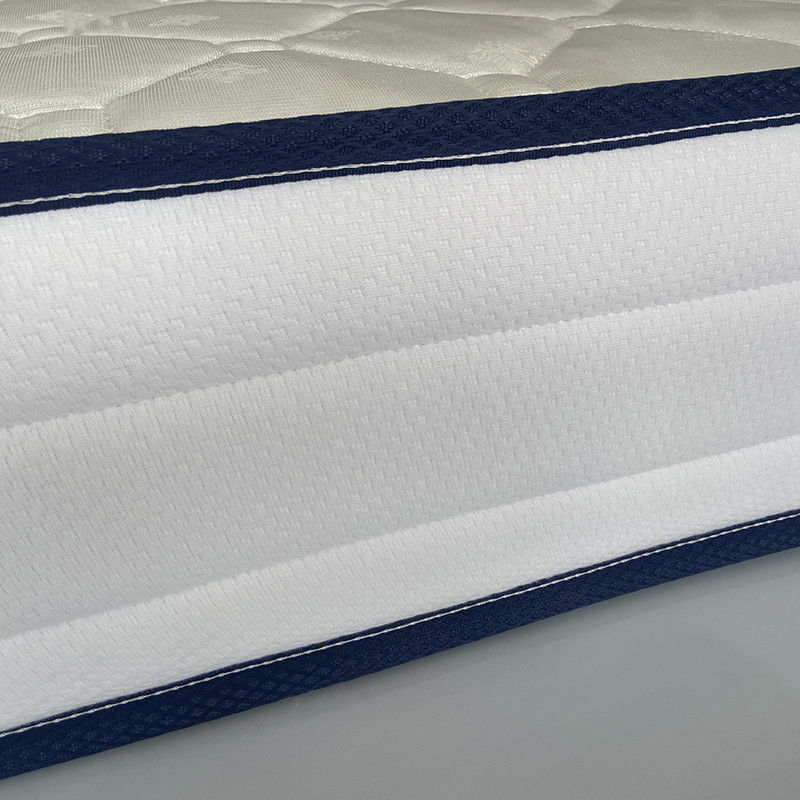

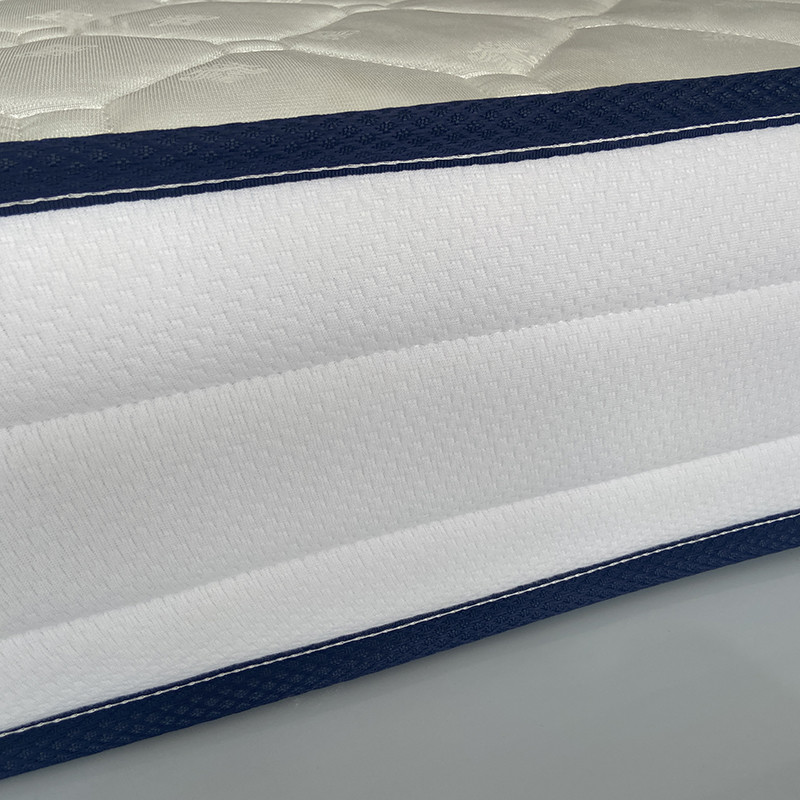

Mattress Sew Machin Tape Edg Automatic Mattress Machine Singer 300U Head

Technical Parameters:

| External size |

2052×1700×820mm |

| Worktable size |

1560×1960mm |

| Chassis drive form |

Reducer |

| Sewing thickness |

30mm-450mm |

| Total power |

1KW |

| Total weight |

600KG |

| Voltage |

380V/220V 50Hz/60Hz 3Phase |

1:PFAFF & SINGER sewing head for your options.

2: Sewing head angle adjusting: 40 degree

3: Worktable lifting form: Screw drive / electric lift

4: Limit switch: Worktable lifting range from 0 to 280mm height.

Advantages:

1: The table can lift and descend in a wide range.

2: The cruising speed of sewing head can be adjusted and can automatically slow

down at the corner.

3: Automatic induction device controls motor clutch for easy operation.

4: Necessities of the mattress production line.

ZLT-TE series include: ZLT-TE5A Fully automatic tape edge machine (With fliping and pulling systems)

ZLT-TE4A Automatic tape edge machine (With flipping system)

ZLT-TE3A Mattress tape edge machine (Manual)

FAQ

1. Q:Are you a Manufacturer?

A:Yes, we are a professional INTELLIGENT MATTRESS EQUIPMENT MANUFACTURER over 16 years.

2. Q: What's your payment terms?

A: T/T 30% in advance ,70% will be before shipment under FOB.

T/T 30% in advance ,70% against the copy of BL under CIF.

T/T 30% in advance ,70% LC at sight under CIF.

*The final explanation of the above payment method belongs to us.

3. Q: What's your delivery time?

A: Depending on the quantity of customers.

Usually mass production models will be delivered within 15 days after receiving deposit .

Customized models require negotiation.

4. Q: How are you doing in quality control?

A: we have the inspection of the quality supervision department every year and issue the inspection report. Each batch of goods will be strictly controlledControlled,there will be quality regulations within the company to ensure that each batch of products are qualified and of the best quality.

5. Q: Can we visit your factory?

A: Warmly welcome, my friends! Once we have your schedule, we will arrange professional sales team to follow up.

6. Q: Where's your factory?

A: Our factory in Juijiang Huangji Crossroad, Jiujiang Town, Nanhai District, Foshan city, Guangdong Province, China.

7. Q: Can you supply other machines?

A: Yes. we also supply below machines and other raw materials:

Mattress Quilting Machine Series

Mattress Hemming Machine Series

Automatic Whole-Plant Mattress Production Line

Mattress (Pocket) Spring Machine Series

Mattress Packing and Rolling Production Line

Mattress Tape Edge Machine Series

Mattress Flanging Machine Series

Raw materials: Knitted cloth, Non-woven cloth, thread, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!