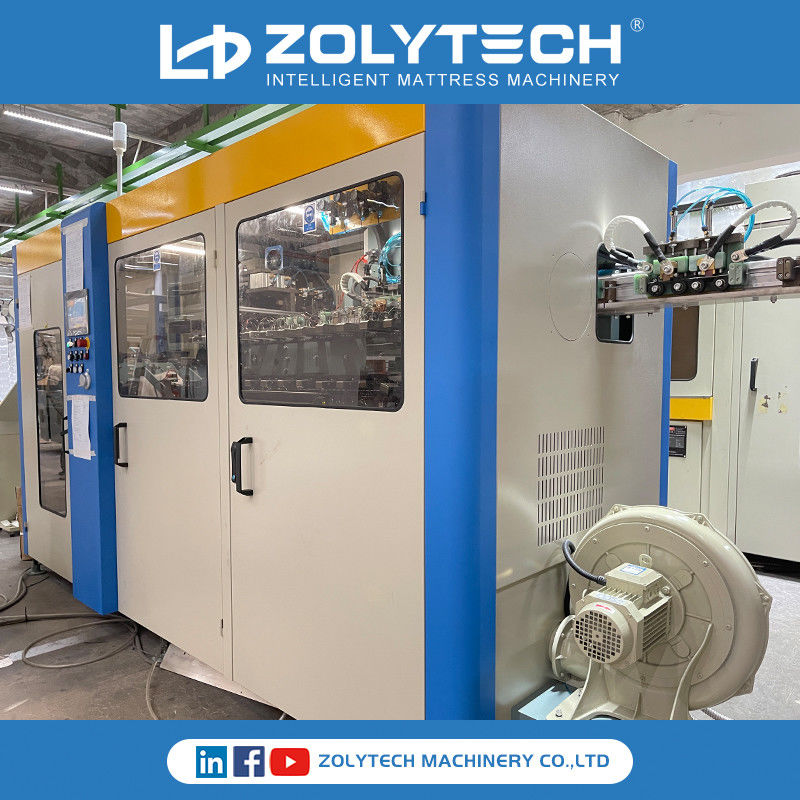

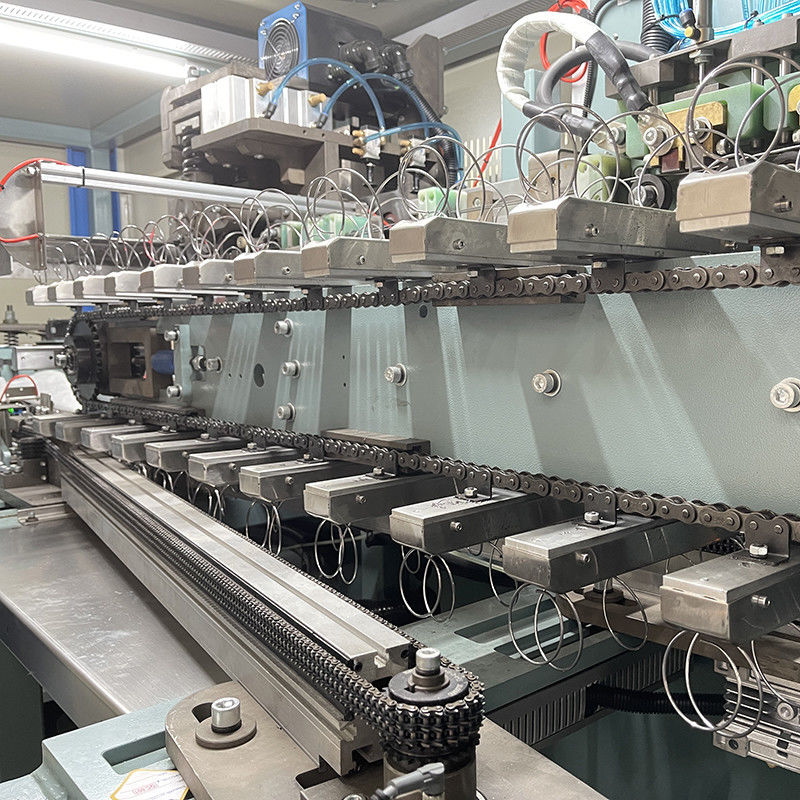

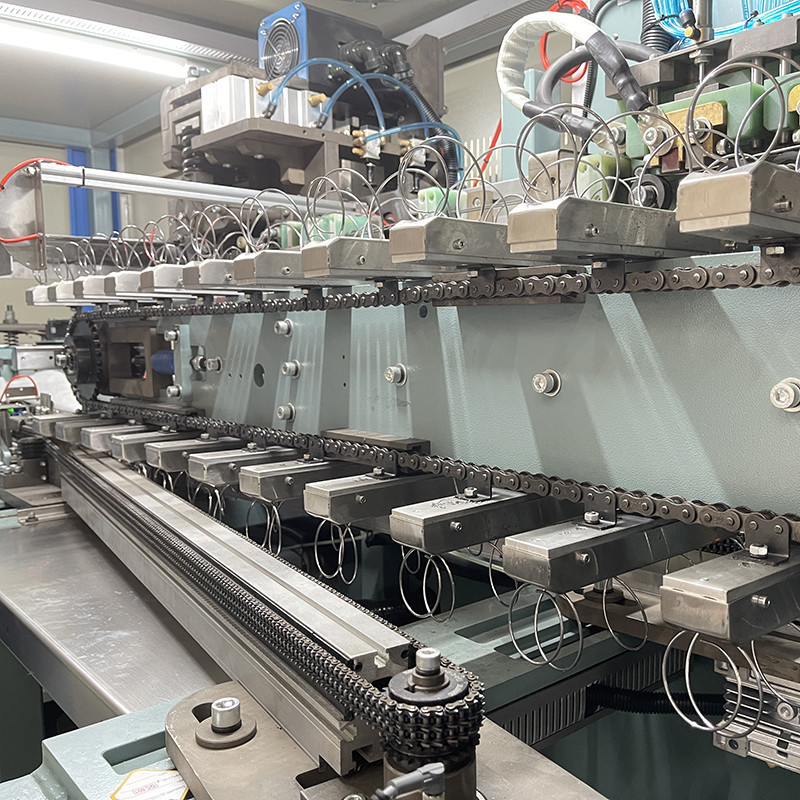

Automatic Pocket Spring Coiling Machine commputerized system pocket spring production line 380V/220V

ZOLYTECH ZLT-PSD180 pocket spring height 260-680mm 180pcs/min computerized Mattress Spring Coiling Machine

Technical parameters:

| Efficiency |

180pcs/min |

| Non-woven supply |

65-90g/m² |

| Non-woven width |

260-680mm |

| Pocket spring height |

60-250mm |

| Wire dia. |

φ1.3-2.3mm |

| Spring core dia. |

φ38-75mm |

| Total power |

40KW for single wire / 43KW for double wires |

| Weight |

4000kg for single wire / 5000kg for double wires |

| Spring shape |

Standard versions:barreland, cylindrical |

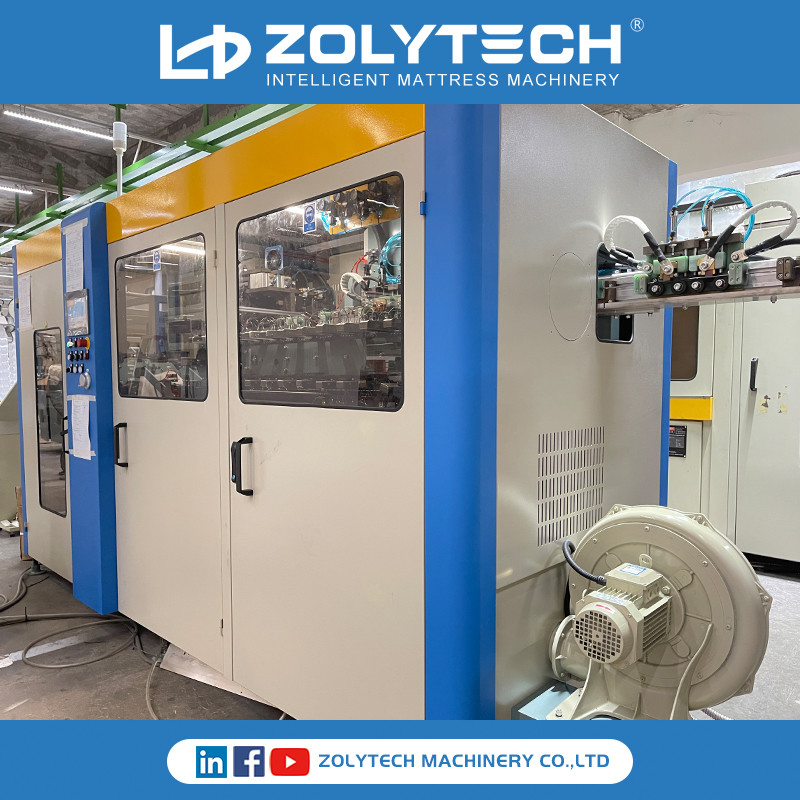

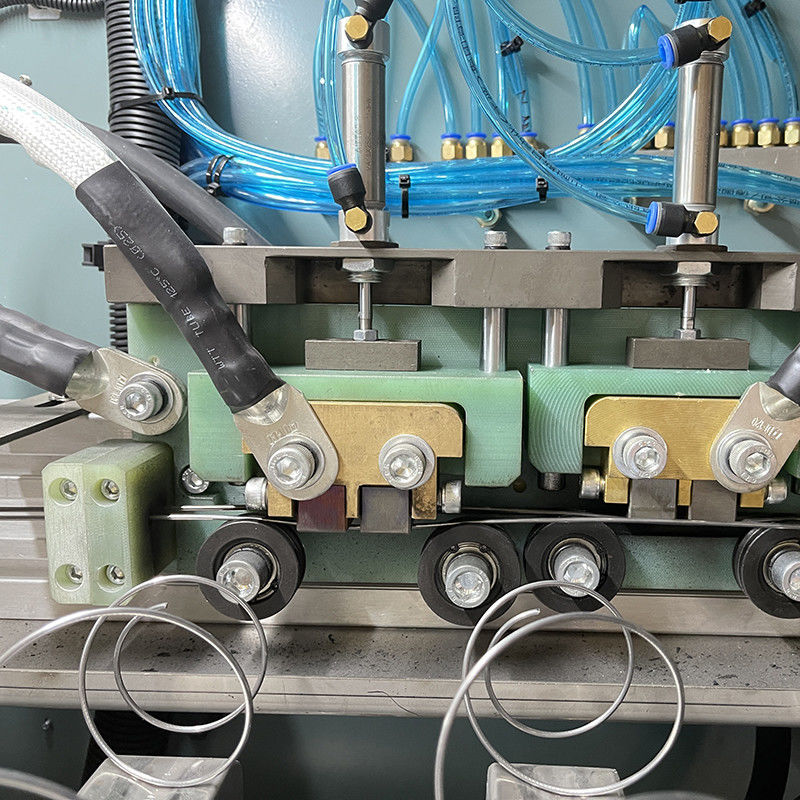

A new generation of patented machine. Providing spring strings with zones from two different wire by D180.

It can make both cylindrical and barrel shape springs.

The heat-treatment device can adopt to differnt spring height, easy for adjustment.

U structure converying belt, carring over 60 magnetic conveying units / good cooling effect.

Real-time monitoring of heat-treatment / intelligent adjustment of temperature.

Automatic non-woven feeder system, material and labor saving.

Multiple fault detecting device, reducing wastage.

Fully automatic single or double wire coiling head, fast and easy adjusting.

Nice structure, easy operating for users.

Special protective device.

Intelligent Mattress Pocket Spring Production Line

It's an ideal accompaliment of pocket spring assembling machine (Model: ZLT-PSA99)

Easy operation; 1 operater only; labor saving significantly!

FAQ

1. Q:Are you a Manufacturer?

A:Yes, we are a professional INTELLIGENT MATTRESS EQUIPMENT MANUFACTURER over 16 years.

2. Q: What supports will you provide during the COVID-19 period?

A: We provide install videos; on-line teaching service and 24 hours on-line stand-by.

3. Q: What's your payment terms?

A: T/T 30% in advance ,70% will be before shipment under FOB.

T/T 30% in advance ,70% against the copy of BL under CIF.

T/T 30% in advance ,70% LC at sight under CIF.

*The final explanation of the above payment method belongs to us.

4. Q: What's your delivery time?

A: Depending on the quantity of customers.

Usually mass production models will be delivered within 15 days after receiving deposit .

Customized models require negotiation.

5. Q: Whats your warranty time ? What you can supply to us after we bought your machine?

A: We provide one year warranty, all machine main parts can be replaced for free within 1 year if broken (not including error operation).

Our engineer available to provided overseas professional technical operation training.

6. Q: Can we visit your factory?

A: Warmly welcome, my friends! Once we have your schedule, we will arrange professional sales team to follow up.

7. Q: Where's your factory?

A: Our factory in Juijiang Huangji Crossroad, Jiujiang Town, Nanhai District, Foshan city, Guangdong Province, China.

8. Q: Can you supply other machines?

A: Yes. we also supply below machines and other raw materials:

Mattress Quilting Machine Series

Mattress Hemming Machine Series

Automatic Whole-Plant Mattress Production Line

Mattress (Pocket) Spring Machine Series

Mattress Packing and Rolling Production Line

Mattress Tape Edge Machine Series

Mattress Flanging Machine Series

Raw materials: Knitted cloth, Non-woven cloth, thread, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!